1.Plastic Bottles Collecting、Cleaning.

2.Make into Bottle Flakes.

3.Make into Recycled Chips.

4.Make into Green Yarn Directly.

5.Directly washing and finishing without dyeing and adding any color master batch.

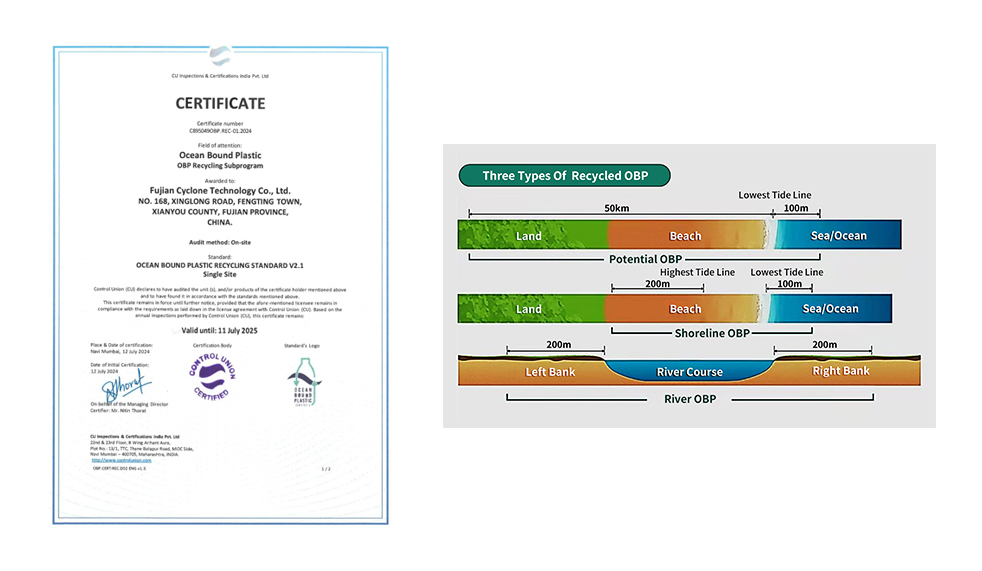

ZerOcean is an environment-friendly fiber made by recycling discarded plastic bottles from the ocean. By using Cyclone,s traceability system to record the source and usage of marine waste plastic bottles, a reuse, and recycling system for marine waste plastic bottles has been established.

CiCLO® biodegradable masterbatch is added during production. Active ingredients embedded in the fiber create pathways that attract naturally occurring microorganisms in end-of-life environments. Ultimately, converting the fiber into natural elements - CO₂, water, methane, and humus, leaving behind no microplastics.

- Advantages

- Accelerates fiber biodegradation leaving only natural elements behind - no microplastics. Aligns with regulations demanding durability and the reduction of microplastic pollution.Maintains integrity of fibers no loss of durability or performance.Process of biodegradation is proven non-toxic to plant life and marine creators.

Through special spinning process, the elasticity and dyeing effect of the fiber is improved.

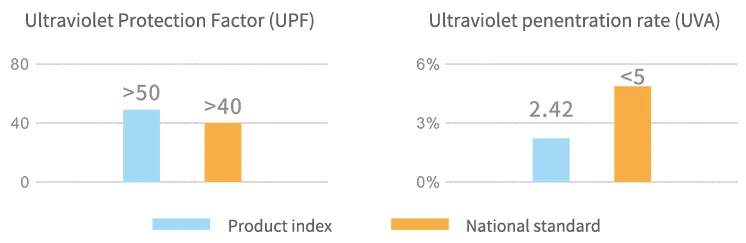

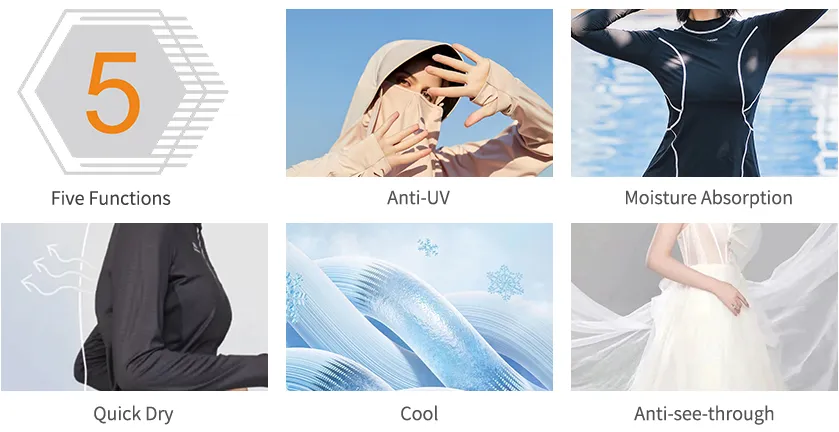

Adding special inorganic powder into the fiber to block and absorb ultraviolet rays at the same time, to achieve a better anti-UV function even if the weight and thickness are reduced.

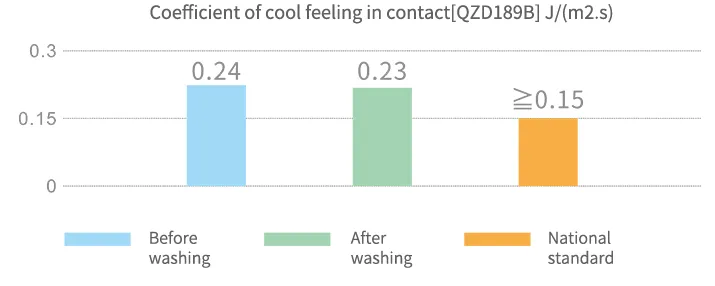

In the spinning process, hydrophilic modification and addition of jade powder with high thermal conductivity are carried out to improve moisture content of polyester; The jade powder also keeps thermal conductivity effect, thus making a cool and comfortable feeling, keeping the fabric breathability and coolness.

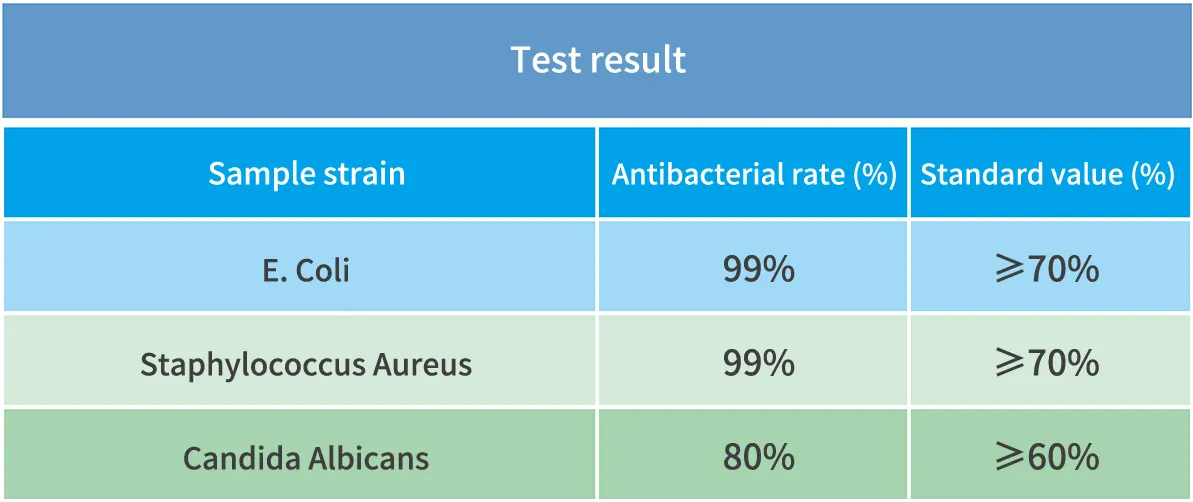

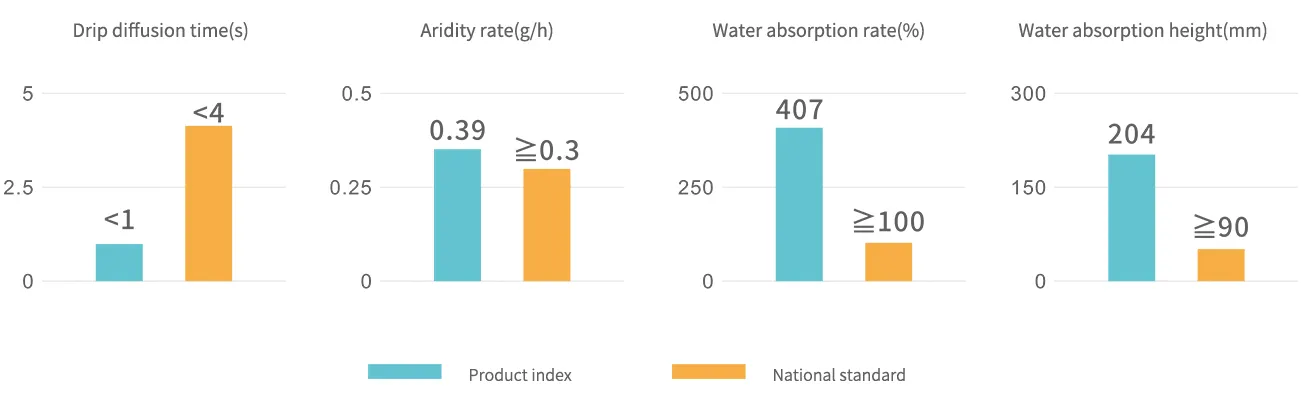

Test result

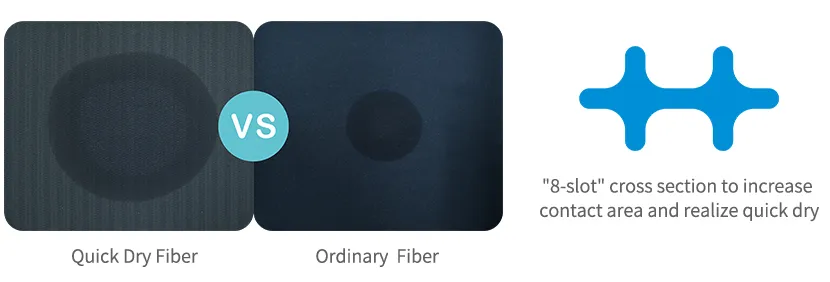

The fiber is added with special medium, using specialshaped cross- section, which allows light to diffuse on the surface ofthe fiber to achieve an anti-see-through effect.

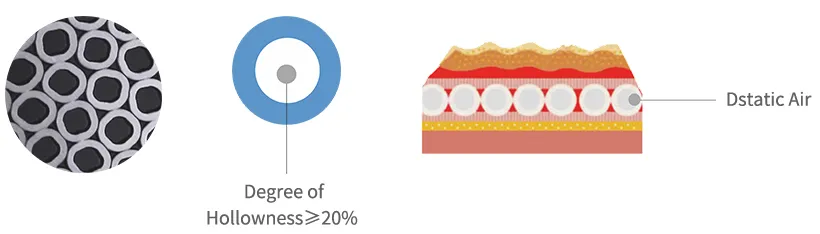

The fiber is manufactured through a special process and has the structure with a hollowness of ≥20%,The fabric is soft, comfortable and warm, light and stylish.

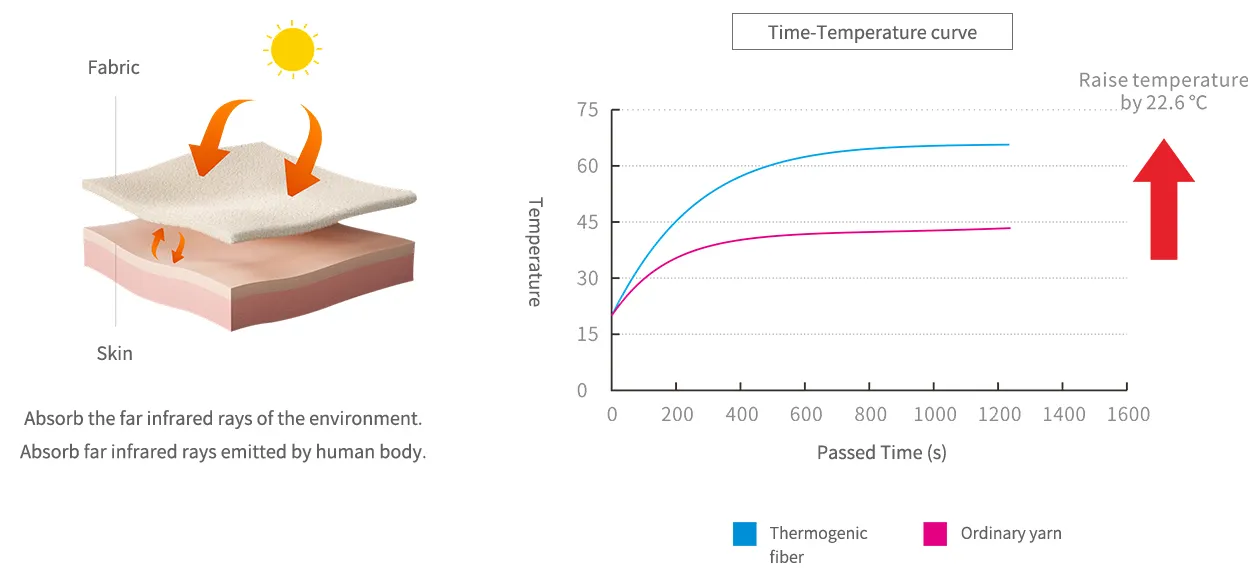

Through adding light-absorption thermogenic masterbatch during the production process, the fiber can absorb heat radiation in different environment, and reduce the loss of human heat by physical heat conversion, thus achieving warm effect.

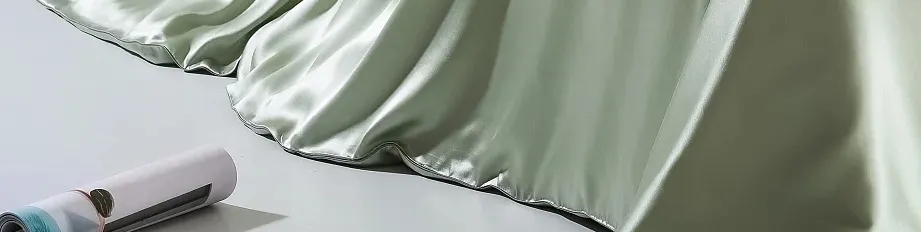

The special spinning process en ables fiber to have the characteristics of different fineness, different cross-section, and different boiling water shrinkage,so as to achieve silk-like, delicate, smooth effects.

By combining DTY with special yarns to give the yarn a comfortable wool feel, which is suitable for weaving fabrics with tight tissue and avoids wrinkles.

High shrinkage yarn and high filaments yarn are compounded to make the material have a good peach-like effect and a soft cotton feel, skin-friendly, rich texture.